The Leaders in Clean Rooms

& Contamination Control

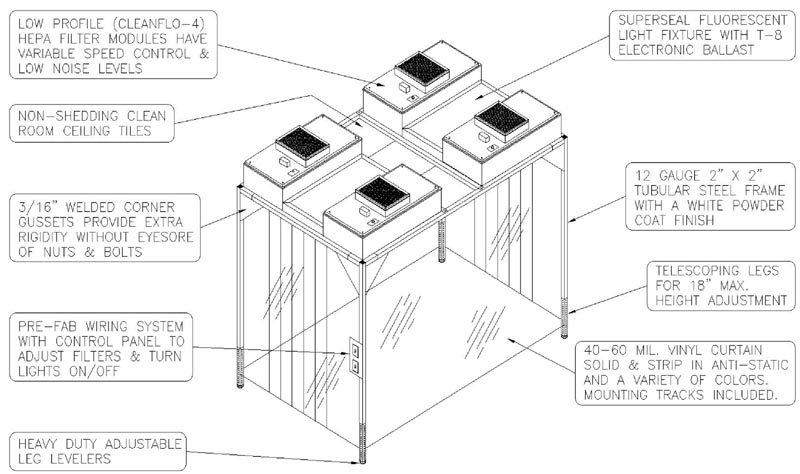

Powder Coated Steel Softwall Clean Rooms - SW Series

Clean Room Depot designed this as a portable solution to create a Class 10-100000 clean room environment without the high cost and constraints of a hard wall system. It’s affordable, reliable, energy efficient and easy to assemble as well as disassemble. The prefabricated wiring system makes electrical hook-up simple with factory wired components and leg-mounted on/off switches for lights and filters. A single point electrical hook-up or heavy duty line cord (under 15 amps) are provided, which may eliminate the need for an expensive installation.

On larger spans our exclusive Rafter/ Truss system eliminates the need for middle and internal legs, thus giving user more available space.

Twenty-five standard sizes are offered, while custom orders are usually fabricated in two weeks.

Specifications

We are offer a wide variety of panel surfaces and systems to meet your specific needs including:

Width O.D.-1 Range: 52-246 in

Length O.D.-2 Range: 52-302 in

Inside Height View: 96 in

Overall Height: 106 in

Required Cleanliness Class/ISO Certification:

10,000/7

10/4

100,000/8

100/5

1000/6

Options

Your clean room can be customized using the following options and components. We also stock a full line of accessories for you.

- ULPA Filters (class 10)

- 5″ Heavy Duty Swivel Locking Casters

- Anti-static Curtain Walls

- Strip, Bi-folding and Dual-flex Doors

- Internal or External Gown Rooms

- 8″ High White Aluminum Fascia around Top Perimeter Room

- Ionization Grids or Bars

- Flow thru Lighting

- 2″ Tubular Stainless Steel Framework

- Comfort Cooling Package

- Magnehelic Gauge to Measure Filter Static Pressure

- Optional Voltage for Lights and HEPA Filters: 230 Volt/277 Volt

- 10″ Diameter Duct on Fan Filters AC Attachment

> Features

> Additional Images

> Test & Certification Services

> Downloads

> Features

Framework:

The rooms are freestanding and fabricated of 12 gauge 2″ x 2″ tubular steel with welded gusset plates on each leg support to insure rigidity. Our exclusive rafter ceiling system allows rooms to span 24′ without need of internal legs. All framework has an electro-statically applied powder coat finish.

Ceiling Grid:

Consists of anodized aluminum hat and zee shaped extrusions that are formed to fit 2″ tubular steel frame. One inch anodized tees make up cross sections creating a leak free ceiling system.

Ceiling Panels:

2′ x 4′ panels manufactured of 5/8″ high density formed fiber core covered with a white vinyl membrane. Tiles are durable, easy to clean and offer both humidity resistance and high light reflection.

Curtains:

Shall be 40 mil clear solid vinyl curtain hung to an appropriate height around perimeter of clean room to maintain proper pressurization. Various types of entry/exit systems are offered to best suit personnel/product flow. (overlaps, strips, bi-folding or dual-flex self closing doors.) Curtains are easily mounted to steel frame by our one piece white PVC mounting track. Simply hook curtains on to track and close the continuous cover. This sleek non-corrosive design creates a tight seal to frame work that prevents contamination from entering the clean room.

Light Fixtures:

There are several types of clean room grade light fixtures used in our softwalls. The type depends on cleanliness level, size and ceiling plan of room design.

-

-

- Class 100 light fixtures

- Class 1000-100000 light fixtures

- Flow thru for class 10 rooms or smaller

- Tear drop

-

HEPA Fan Filter Modules:

Filtration provided by Cleanflo-4 fan filter modules. These self contained units have an aluminum housing and features a variable speed control and have a true pleated prefilter. HEPA filter efficiency to be 99.99% at 0.3 microns and produce 720 to 800 c.f.m. or an average velocity of 90 f.p.m.

Electrical:

A prefabricated wiring system is supplied to speed up installation and reduce wiring costs. Assembly personnel just plug electrical components together so an electrician is only needed to connect power to a single point junction box. What makes this system completely user friendly is a leg mounted control box with separate on/off switches for HEPA filters and light fixtures.

Assembly:

Installation of Clean Room Depot’s softwall systems are quick and easy with our simple step by step assembly manual, all parts components are clearly labeled so installation can be complete within hours.

> Additional Images

> Test & Certification Services

A well-conceived, properly administered maintenance program is a requirement for an efficient clean facility. The effectiveness of this maintenance program can be measured by regular testing of the facility by a Clean Room Depot technician.

A program of periodic inspection can be established on a quarterly, semi-annual basis. A customized testing program can be developed from the menu of tests presented below. Once a program has been initiated, the scheduling of on-site testing will be accomplished automatically.

The aim of the testing program is to monitor facility performance to identify significant changes in efficiency. Such changes can be addressed before they become a major problem resulting in decreased product quality or unplanned facility downtime.

During a typical certification test, the technician will identify areas of concern and make the client aware of them. Adjustments will be made as necessary to bring the room into compliance with client standards and/or other pertinent standards. Recommendations and cost estimates for procedures necessary to bring the facility into compliance will also be offered. Upon completion of the test procedure, a Certificate of Conformance and supporting test report will be submitted to the client.

Typical Test and Procedures per ISO Requirements

- Cleanliness levels per ISO and Federal Standard 209

- Particle size and quantity count

- Temperature control range test

- Humidity control range test

- Filter pressure drop measurements

- Air flow quantity measurements

- Air flow velocity measurements

- Noise level checks

- Light level checks

- Room pressurization

> Downloads

Our Clean Room Experts are Ready to Help Specify and Quote Your Needs.